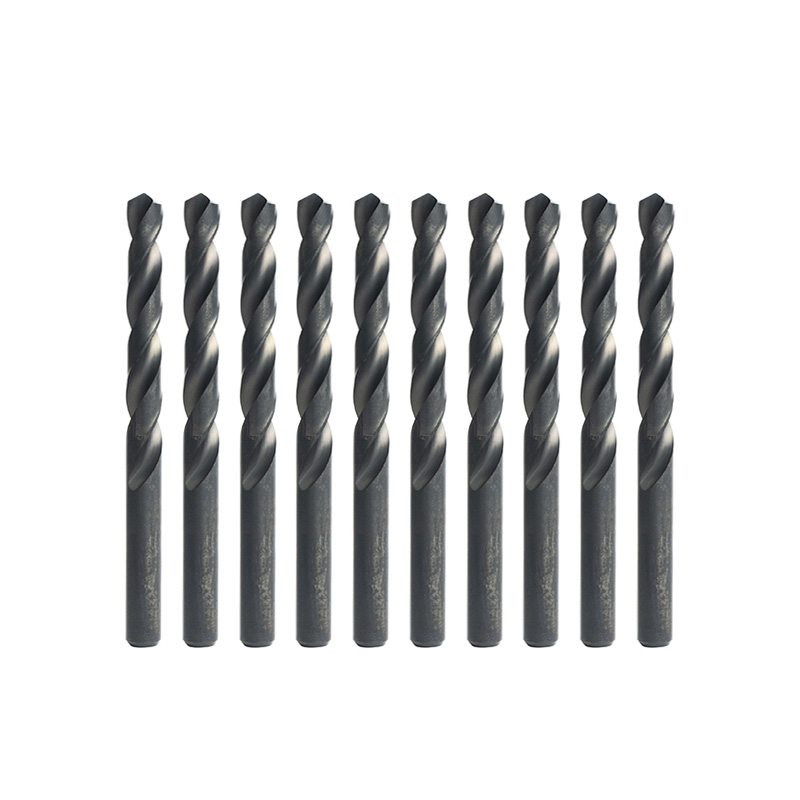

Black Oxide Ƙirƙirar HSS mai aiki tsawon Twist Drill Bits

Amfani

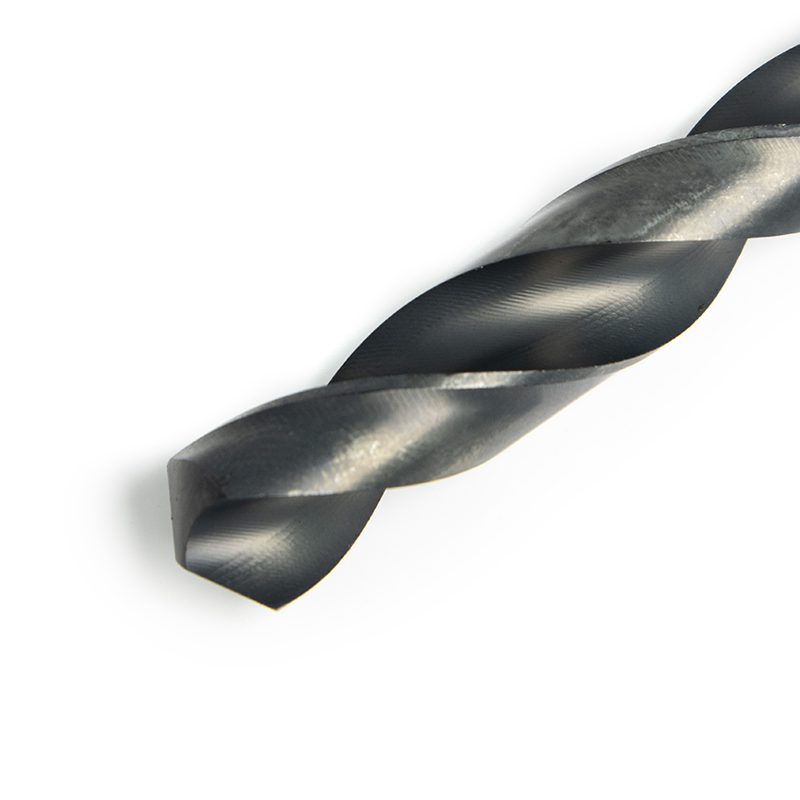

1. Tauri da Dorewa: Ƙirƙirar HSS drill bits an san su da tsayin daka da tsayin daka, yana sa su dace da hakowa cikin abubuwa masu wuya kamar ƙarfe, itace, da filastik. Tsarin ƙirƙira yana haɓaka ƙarfin rawar rawar soja, yana tabbatar da aiki mai dorewa.

2. Juriya na zafi: Black oxide shafi a kan HSS rawar soja yana ba da juriya na zafi, rage raguwa da zafi da aka haifar a lokacin hakowa. Wannan yana taimakawa wajen hana ɗimbin rawar jiki daga zazzaɓi kuma yana tsawaita rayuwarsa, ko da lokacin hakowa ta kayan aiki masu tauri.

3. Juriya na Lalata: Har ila yau, murfin oxide na baki yana samar da wani nau'i na juriya na lalata, yana kare kullun daga tsatsa da lalata. Wannan yana da fa'ida musamman lokacin aiki da kayan ƙarfe.

4. Inganta Lubricity: Rufin baƙin ƙarfe oxide yana rage raguwa kuma yana aiki azaman mai mai a lokacin hakowa. Wannan yana haifar da aikin yankan santsi, rage yawan zafin rana, da ƙara kwararar guntu, wanda a ƙarshe ya tsawaita rayuwar ɗan wasan.

masana'anta

Amfani

1. Ƙarfe Hakowa: Ƙarfe na baƙin ƙarfe oxide ya yi fice wajen hakowa ta nau'ikan karafa daban-daban, waɗanda suka haɗa da ƙarfe, aluminum, tagulla, da bakin karfe. Ana amfani da su don ayyuka kamar ƙirƙirar ramuka don kusoshi, screws, ko rivets, da kuma aikin ƙirar ƙarfe na gaba ɗaya da aikin gyarawa.

2. Aikin katako: Hakanan waɗannan ƙwanƙwasa sun dace da hako ramuka a cikin itace, yana sa su dace da ayyukan aikin katako. Ana iya amfani da su don ƙirƙirar ramuka don dowels, screws, ko wasu kayan ɗamara, da kuma ayyukan aikin kafinta na gaba ɗaya.

3. Filastik da Hakowa Haɗe-haɗe: Za a iya amfani da ƙirƙira ƙirƙira baƙar oxide drills don haƙo ramuka a cikin kayan filastik, kamar bututun PVC ko zanen acrylic. Hakanan suna da tasiri don hakowa ta hanyar kayan haɗin gwiwa kamar fiberglass.

4. Gabaɗaya DIY da Inganta Gida: Ƙirƙirar baƙar fata oxide drills sune kayan aiki iri-iri don ayyukan DIY daban-daban da ayyukan haɓaka gida. Ana iya amfani da su don ayyuka kamar rataye shelves, shigar da sandunan labule, harhada kayan daki, da ƙari.

| Diamita (mm) | sarewa Tsawon (mm) | Gabaɗaya Tsawon (mm) | Diamita (mm) | sarewa Tsawon (mm) | Gabaɗaya Tsawon (mm) | Diamita (mm) | sarewa Tsawon (mm) | Gabaɗaya Tsawon (mm) | Diamita (mm) | sarewa Tsawon (mm) | Gabaɗaya Tsawon (mm) |

| 0.5 | 6 | 22 | 4.8 | 52 | 86 | 9.5 | 81 | 125 | 15.0 | 114 | 169 |

| 1.0 | 12 | 34 | 5.0 | 52 | 86 | 10.0 | 87 | 133 | 15.5 | 120 | 178 |

| 1.5 | 20 | 43 | 5.2 | 52 | 86 | 10.5 | 87 | 133 | 16.0 | 120 | 178 |

| 2.0 | 24 | 49 | 5.5 | 57 | 93 | 11.0 | 94 | 142 | 16.5 | 125 | 184 |

| 2.5 | 30 | 57 | 6.0 | 57 | 93 | 11.5 | 94 | 142 | 17.0 | 125 | 184 |

| 3.0 | 33 | 61 | 6.5 | 63 | 101 | 12.0 | 101 | 151 | 17.5 | 130 | 191 |

| 3.2 | 36 | 65 | 7.0 | 69 | 109 | 12.5 | 01 | 151 | 18.0 | 130 | 191 |

| 3.5 | 39 | 70 | 7.5 | 69 | 109 | 13.0 | 101 | 151 | 18.5 | 135 | 198 |

| 4.0 | 43 | 75 | 8.0 | 75 | 117 | 13.5 | 108 | 160 | 19.0 | 135 | 198 |

| 4.2 | 43 | 75 | 8.5 | 75 | 117 | 14.0 | 108 | 160 | 19.5 | 140 | 205 |

| 4.5 | 47 | 80 | 9.0 | 81 | 125 | 14.5 | 114 | 169 | 20.0 | 140 | 205 |