Morse Taper Shank HSS End Mills

Siffofin

1. Morse Taper Shank: Ƙarshen niƙa yana da shank wanda aka ƙera don dacewa da igiya na Morse Taper. Tsarin Morse Taper yana ba da damar amintacce kuma daidaitaccen hawan injin ƙarshen a cikin injin niƙa.

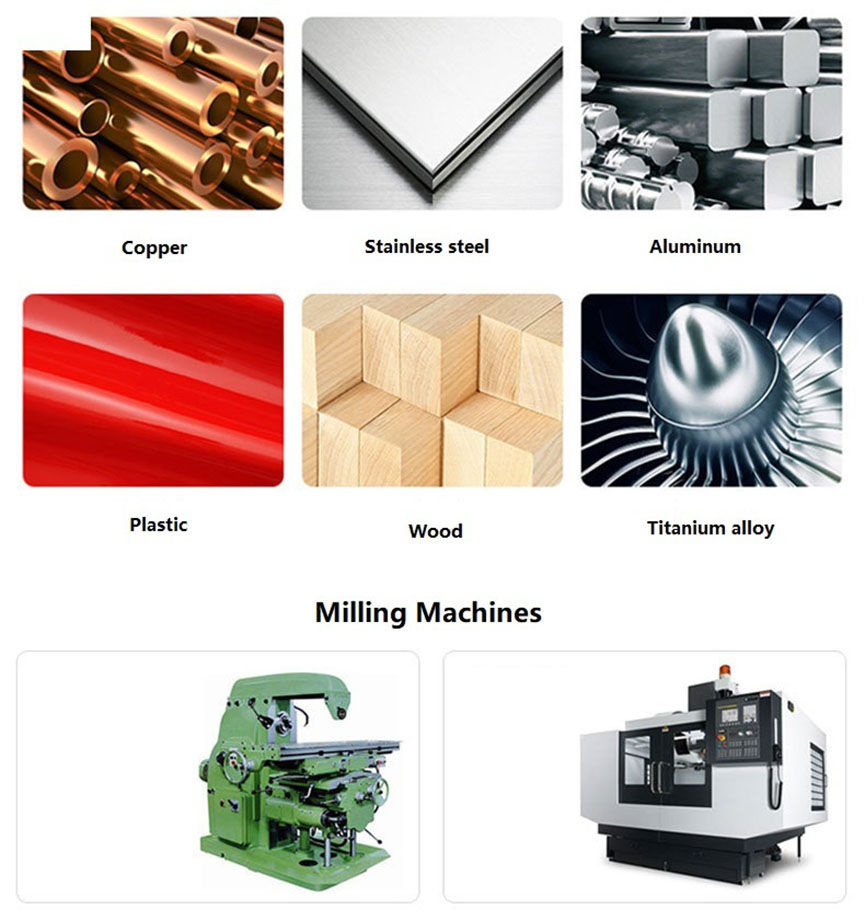

2. Ƙarfe Mai Girma (HSS): HSS wani nau'i ne na kayan aiki na kayan aiki da aka saba amfani da shi wajen yanke kayan aiki. HSS ƙarshen niƙa an san su don taurinsu, juriya na zafi, da kuma iya jure babban saurin yankewa. HSS ƙarshen niƙa sun dace da abubuwa da yawa, gami da ƙarfe na carbon, ƙarfe na ƙarfe, bakin karfe, da ƙarfe mara ƙarfe.

3. sarewa: Ƙarshen niƙa zai sami sarewa da yawa tare da tsayinsa. sarewa sune madaidaitan tsagi ko madaidaicin saman saman injin niƙa. Sarewa na taimakawa wajen fitar da guntu da samar da yankan gefuna don cire kayan. Yawan sarewa na iya bambanta dangane da aikace-aikacen, tare da zaɓuɓɓukan gama gari sune sarewa 2, 4, ko 6.

4. Yanke Geometry: Ƙarshen HSS suna zuwa a cikin nau'i-nau'i daban-daban na yankan geometries, kamar ƙarshen murabba'i, hancin ball, radius na kusurwa, ko chamfer. Kowane geometry ya dace da takamaiman ayyukan niƙa da ƙare saman da ake so.

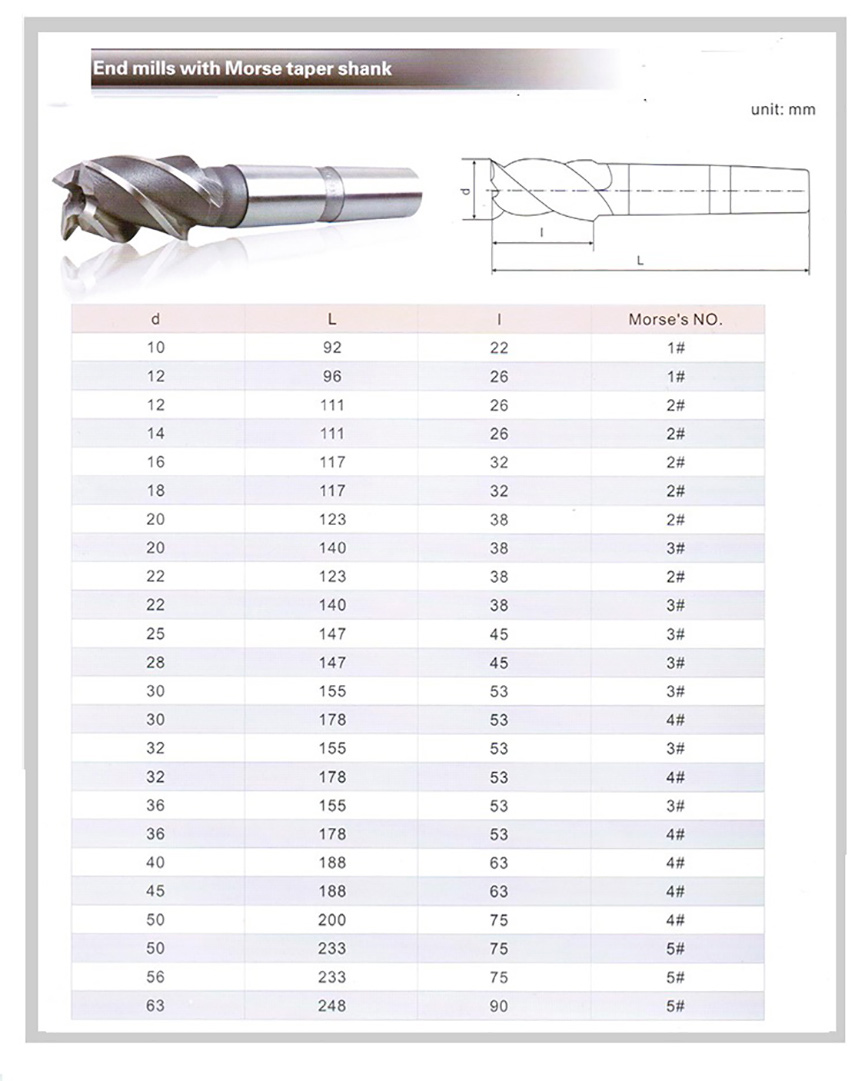

5. Tsawon Tsawon Gabaɗaya da Tsawon sarewa: Tsawon tsayin daka yana nufin jimlar tsayin ƙarshen niƙa, daga ƙarshen yankan zuwa ƙarshen shank. Tsawon sarewa yana nufin tsayin yanki ko sarewa. Akwai tsayi daban-daban don ɗaukar zurfin niƙa daban-daban da buƙatun sharewa.

6. Rufi Zaɓuɓɓuka: HSS karshen niƙa iya kuma zo da daban-daban shafi zažužžukan kamar TiN, TiCN, ko TiAlN. Wadannan suturar suna ba da ingantaccen juriya na lalacewa, haɓaka rayuwar kayan aiki, da mafi kyawun aiki a cikin aikace-aikacen yankan sauri ko yanayin zafi.

7. Standard Sizes: Morse Taper shank HSS karshen Mills suna samuwa a daidaitattun masu girma dabam da suka dace da Morse Taper nadi (MT1, MT2, MT3, da dai sauransu). Waɗannan masu girma dabam suna tabbatar da dacewa daidai da dacewa tare da injunan niƙa da igiya.

masana'anta

Morse taper shank HSS cikakken bayanin niƙa

Amfani

1. Amintacce kuma Daidaitaccen Hauwa: Morse Taper shank yana samar da amintacce kuma daidaitaccen dacewa a cikin sandar, rage gudu da kuma tabbatar da ingantaccen yankewa. Wannan yana taimakawa tabbatar da daidaiton daidaiton girma da ƙarewar ƙasa a cikin sassan injina.

2. Versatility: Morse Taper shank HSS ƙarshen niƙa suna samuwa a cikin nau'i-nau'i masu yawa da geometries, suna sa su dace da ayyuka daban-daban na milling da nau'in kayan aiki. Wannan juzu'i yana ba da damar yin amfani da aikace-aikacen da yawa ba tare da buƙatar saitin kayan aiki da yawa ba.

3. Dorewa da Juriya na Heat: HSS ƙarshen niƙa an san su da ƙarfi da juriya ga zafi. Za su iya tsayayya da babban saurin yankewa kuma suna kula da aikin yanke su ko da a ƙarƙashin zafi mai zafi da aka haifar a lokacin machining. Wannan dorewa yana fassara zuwa rayuwar kayan aiki mai tsayi, rage yawan sauyawar kayan aiki da raguwa a cikin aikin injin.

4. Cost-Tasiri: HSS karshen Mills ne kullum mafi tsada-tasiri idan aka kwatanta da sauran high-yi kayan aiki kayan aiki, kamar carbide. HSS ƙarshen niƙa yana ba da ma'auni mai kyau tsakanin aiki da farashi, yana mai da su zaɓin da ya dace don ƙananan injin ƙira, ƙalubale, ko aikace-aikace tare da ƙarancin buƙatu.

5. Daidaituwa: Morse Taper shank HSS ƙarshen niƙa an tsara su don dacewa da daidaitattun ƙirar Morse Taper waɗanda aka saba samu a cikin injin milling. Wannan daidaituwa yana sauƙaƙe saitin kayan aiki, yana rage buƙatar ƙarin adaftan, kuma yana ba da damar musanyawa cikin sauƙi tsakanin kayan aikin daban-daban.

6. Ƙarfafa Ƙarfafawa: Ƙarshen Ƙarshen HSS na iya zama sauƙi a sake gyarawa, ƙara rayuwarsu mai amfani da rage farashin kayan aiki a kan lokaci. Tare da kulawa mai kyau da kaifi, HSS ƙarshen niƙa zai iya sadar da daidaiton aiki da ƙima akan zagayowar injina da yawa.

7. Wide Material Compatibility: HSS karshen Mills iya yadda ya kamata inji da fadi da kewayon kayan, ciki har da carbon karfe, gami karfe, bakin karfe, jefa baƙin ƙarfe, wadanda ba ferrous karafa, da kuma robobi. Wannan juzu'i yana sa su dace da masana'antu da aikace-aikace iri-iri.