Solid Carbide roughing End Mill

Siffofin

1. High abu kau kudi: Tungsten carbide roughing karshen Mills an tsara tare da m sarewa idan aka kwatanta da misali karshen Mills. Wannan yana ba da damar ɗaukar nauyin guntu mafi girma da ƙarin aikin yanke hukunci, yana haifar da ƙimar cire kayan abu mafi girma. Sun dace don cire abubuwa masu yawa da sauri a cikin ayyukan roughing.

2. Babban tauri da juriya: Tungsten carbide sananne ne don taurinsa na musamman da juriya ga lalacewa. Wannan ya sa roughing karshen niƙa da aka yi daga tungsten carbide sosai m, ko da lokacin da machining wuya kayan kamar bakin karfe, gami karfe, ko jefa baƙin ƙarfe.

3. M hakori zane: Roughing karshen Mills yawanci ƙunshi girma da kuma mafi yadu sarari yankan hakora idan aka kwatanta da sauran karshen niƙa. Wannan ƙirar tana taimakawa don cimma ingantaccen ƙaurawar guntu kuma yana hana guntuwar guntu, tabbatar da ayyukan yankan santsi.

4. Chip breakers: Wasu tungsten carbide roughing karshen niƙa iya samun guntu breakers ko guntu splitters a kan yankan gefuna. Waɗannan fasalulluka suna taimakawa wajen karya dogayen kwakwalwan kwamfuta zuwa ƙarami, mafi ƙarancin sarrafawa, haɓaka mafi kyawun ƙaurawar guntu da rage haɗarin lalacewar aiki.

5. Babban zafi mai zafi: Ƙarfin zafin jiki na tungsten carbide yana ba da damar roughing ƙarshen niƙa don tsayayya da zafi da aka haifar yayin cire kayan abu mai nauyi. Wannan juriya na zafi yana taimakawa hana nakasar kayan aiki ko gazawar kayan aiki da bai kai ba, yana tabbatar da tsawon rayuwar kayan aiki.

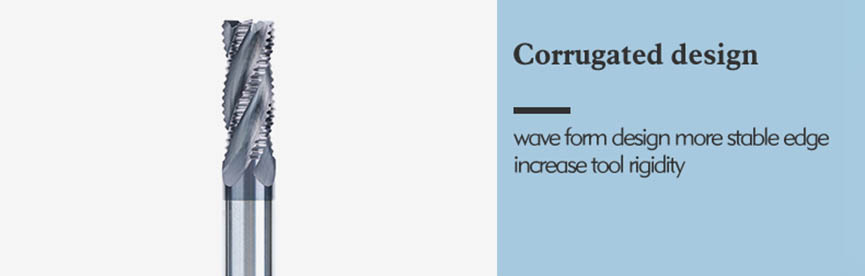

6. Maɓalli mai iya canzawa ko ƙirar farar mai canzawa: Wasu roughing ƙarshen niƙa suna da madaidaicin heliks ko ƙirar farar canji a kan sarewarsu. Wannan fasalin yana taimakawa wajen rage zance da rawar jiki yayin aiwatar da yankan, yana haifar da haɓakar haɓakar ƙasa da haɓaka kwanciyar hankali na kayan aiki.

7. Zaɓuɓɓukan sutura: Za'a iya rufe maƙallan ƙarfe na ƙarshe tare da sutura daban-daban, kamar TiAlN, TiCN, ko AlTiN. Waɗannan sutura suna haɓaka aikin kayan aiki ta hanyar rage juzu'i, haɓaka kwararar guntu, da haɓaka juriya. Zaɓin zaɓi mai dacewa ya dogara da takamaiman aikace-aikacen da kayan aiki.

8. Ƙarfafa gini: Tungsten carbide roughing ƙarshen niƙa an gina su tare da ƙaƙƙarfan gini mai ɗorewa don jure buƙatun ayyukan roughing. An ƙera su don ɗaukar manyan runduna masu yankewa da kuma samar da kwanciyar hankali yayin cire kayan abu mai nauyi.

9. Zaɓuɓɓukan Shank: Tungsten carbide roughing ƙarshen niƙa suna samuwa tare da zaɓuɓɓukan shank daban-daban, gami da madaidaiciya madaidaiciya, ƙwanƙolin Weldon, ko ƙwanƙwasa na Morse. Zaɓin shank ɗin ya dogara da ma'aunin kayan aikin injin da takamaiman buƙatun saitin mashin ɗin.

10. Tool geometries: Roughing karshen Mills iya samun takamaiman kayan aiki geometries don inganta yankan yi. Waɗannan geometries na iya haɗawa da ƙarin diamita na tsakiya, ƙarfafan radiyoyin kusurwa, ko shirye-shirye na musamman don haɓaka ƙarfin kayan aiki da aiki yayin ayyukan roughing.

Nuni dalla-dalla

FARKO