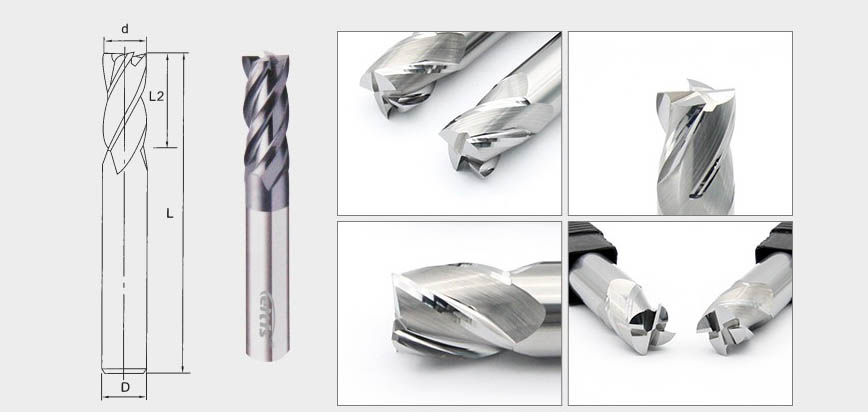

Solid Carbide Square Mills don injin gabaɗaya

Siffofin

1. Abu: An yi daskararren filayen ƙarewar carbide daga wani yanki guda na carbide guda, wanda ke tabbatar da babban karko da juriya don sa da tsagewa.

2. Hardness: Carbide an san shi da taurin sa na musamman. M carbide murabba'in karshen Mills iya jure high yankan gudu da kuma kula da kaifinsu na dogon lokaci idan aka kwatanta da sauran kayan.

3. Madaidaici: M carbide square ƙarshen niƙa an tsara tare da madaidaicin tunani. Suna da ikon samar da ingantattun yankewa da tsafta, wanda ke haifar da daidaitattun kayan aiki masu inganci.

4. Ƙarfafawa: Ana iya amfani da waɗannan masana'antun ƙarewa a cikin nau'o'i daban-daban, ciki har da ƙarfe na ƙarfe da na ƙarfe, robobi, da abubuwan haɗin gwiwa. Wannan ƙwanƙwasa yana sa su dace da aikace-aikacen injina da yawa.

5. Efficiency: M carbide square karshen Mills an tsara tare da mahara sarewa, wanda bunkasa guntu fitarwa da kuma rage chances na clogging. Wannan yana inganta aikin injina da yawan aiki gaba ɗaya.

6. Heat juriya: Carbide yana da kyau kwarai zafi juriya Properties, kyale m carbide square karshen Mills yi tsayayya high yanayin zafi generated a lokacin yankan ayyuka ba tare da rasa su taurin ko kaifi.

7. Longevity: Saboda su high taurin da karko, m carbide square karshen Mills da tsawon rayuwa idan aka kwatanta da sauran nau'i na karshen. Wannan yana haifar da ƙarancin maye gurbin kayan aiki, rage raguwa da farashi.

8. High rigidity: M carbide karshen Mills da high rigidity, ma'ana ba su da wuya a lankwasa ko karkata a lokacin da machining ayyukan. Wannan rigidity yana haifar da ingantacciyar kwanciyar hankali da daidaiton girma.

9. Zaɓuɓɓukan sutura: Ƙarshen ƙarfe na ƙarshen ƙarshen carbide mai ƙarfi kuma za'a iya rufe shi da sutura daban-daban kamar TiN, TiCN, da TiAlN, waɗanda ke ƙara haɓaka aikin su ta hanyar rage juzu'i, haɓaka rayuwar kayan aiki, da haɓaka ƙaurawar guntu.

10. Yankan-baki lissafi: M carbide square karshen Mills suna samuwa a daban-daban yankan-baki geometries, kamar madaidaiciya, helical, kuma m heliks kayayyaki. Waɗannan geometries suna ba da halaye daban-daban na yankan kuma suna biyan takamaiman buƙatun injin.

Nuni dalla-dalla

FARKO

Amfani

1. Durability: M carbide square karshen Mills an san su na kwarai karko. Kayan Carbide yana da juriya ga lalacewa kuma yana iya jure babban saurin yankewa da kayan abrasive, yana haifar da tsawon rayuwar kayan aiki.

2. High Speed Machining: M carbide square karshen Mills iya nagarta sosai yin high-gudun machining ayyuka saboda taurin da zafi juriya. Wannan yana ba da damar ƙara yawan aiki da ɗan gajeren lokutan inji.

3. Madalla Chip fitarwa: The sarewa a kan m carbide square karshen niƙa an tsara su don inganta guntu fitarwa. Wannan yana taimakawa hana haɓakar guntu kuma yana tabbatar da yanke santsi, rage haɗarin lalacewar kayan aiki ko lahani na aiki.

4. Inganta Surface Gama: M carbide square karshen niƙa samar da tsabta da kuma daidai cuts, sakamakon a m surface gama a kan workpiece. Wannan yana kawar da buƙatar ƙarin matakan ƙarewa, adana lokaci da farashi.

5. Versatility: M carbide murabba'in ƙarshen niƙa sun dace da nau'ikan kayan aiki, gami da ƙarfe, robobi, da abubuwan haɗin gwiwa. Wannan juzu'i ya sa su dace don masana'antu daban-daban, daga kera motoci zuwa sararin samaniya.

6. An inganta kwanciyar hankali: Square Carbide Square ƙare Mills Mills Strates, wanda ke rage ƙirar kayan aiki da haɓakar yankan kwanciyar hankali. Wannan yana haifar da ingantattun daidaiton ƙima da rage damar karyewar kayan aiki.

7. Daidaitaccen Machining: The kaifi yankan gefuna na m carbide square karshen Mills damar domin daidai da kuma m machining. Wannan yana da mahimmanci ga aikace-aikacen da ke buƙatar juriya mai ƙarfi da cikakkun bayanai masu rikitarwa.

8. Juriya na Heat: Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfafa zai iya tsayayya da yanayin zafi mai zafi da aka haifar a lokacin machining. Wannan juriya na zafi yana hana kayan aiki daga laushi ko rasa kaddarorin yankansa, yana tabbatar da daidaiton aiki.

9. Yawan canje-canje na kayan aiki: Millsalan katako mai ƙarfi na Carbide suna da rayuwa mafi tsayi idan aka kwatanta da wasu kayan, rage buƙatar buƙatar canje-canje kayan aiki akai-akai. Wannan yana haifar da haɓaka haɓakar samarwa da rage raguwar lokaci.

10. Cost-Tasiri: Ko da yake da farko ya fi tsada, m carbide square karshen Mills bayar da dogon lokacin da kudin tanadi saboda su Extended kayan aiki rayuwa da high-yi capabilities. Wannan ya sa su zama zaɓi mai tsada don ayyukan masana'antu.

| Diamita na ruwa (mm) | Tsawon ruwa (mm) | Cikakkun (mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |