Tungsten Carbide roughing End Mill

Siffofin

Carbide roughing ƙarshen niƙa suna da manyan fa'idodi da yawa:

1. Wadannan masana'antun ƙare an tsara su don cire kayan aiki yadda ya kamata a lokacin roughing, suna sa su dace da mashin mai sauri da cire kayan abu mai nauyi.

2. An yi shi da babban ingancin tungsten carbide, waɗannan injinan ƙarshen suna ba da ƙarfi da ƙarfi don jure wa ƙaƙƙarfan aikace-aikacen roughing.

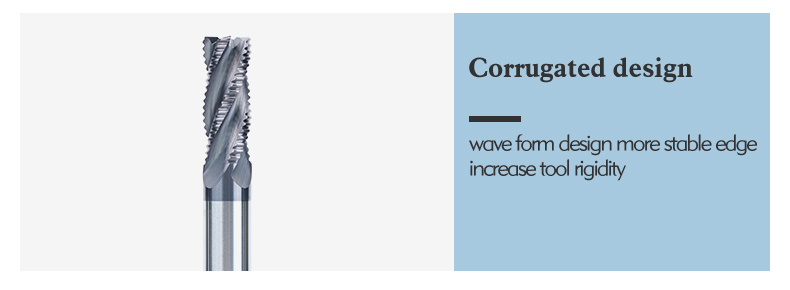

3. Roughing karshen Mills ƙunshi wani m hakori zane cewa facilitates iko yankan da guntu fitarwa, haifar da sauri abu kau rates.

4. Dace da m machining na iri-iri na kayan, ciki har da karfe, bakin karfe, jefa baƙin ƙarfe da sauran ferrous da nonferrous karfe kayan.

5. Ƙarshen masana'anta an tsara su don tsayayya da yanayin zafi mai zafi da aka haifar a lokacin roughing, rage girman nakasar zafi da kuma tabbatar da tsawon rayuwar kayan aiki.

6. Wasu roughing karshen niƙa iya ƙunshi musamman coatings kamar TiCN (titanium carbonitride) ko AlTiN (aluminum titanium nitride) don bunkasa lalacewa juriya da kuma mika kayan aiki ta amfani a karkashin m machining yanayi. rayuwa.

7. Ƙarshen masana'anta an ƙera su don samar da kwanciyar hankali da tsayin daka a lokacin yankan m, rage rawar jiki da kuma tabbatar da daidaiton aiki.

8. Haɓaka ƙirar tsagi na cire guntu da kuma juzu'in juzu'i, wanda ke da amfani ga ingantaccen cire guntu, yana hana sake yanke guntu, da haɓaka ingantaccen aiki.

KYAUTATA NUNA